Scotch™ Brand recently rolled out its latest packaging innovation made from 100% recycled paper, Scotch™ Cushion Lock™ Protective Wrap. A sustainable alternative to plastic cushion wrap, Cushion Lock is an expanding paper wrap that offers nested protection to immobilize packaged items while on the move, no matter how bumpy the transit process may be.

Proven to protect, this innovative wrap expands 60 times its original volume to fill packing boxes with less material, eliminating the need for additional packing supplies typically required to secure and stabilize contents. Upon arrival at its destination, Cushion Lock can be easily recycled in a curbside recycling bin.

“3M applies science to life, developing innovative solutions for the world’s challenges. In developing Cushion Lock, we set out to reinvent packaging. Plastic bubble has been a trusted shipping solution for decades. We wanted to create a product that replicates the protective and cushioning qualities of plastic bubble while eliminating the need for plastic. Cushion Lock is a curbside recyclable product that expands, protects and cushions shipping products,” said Mark Copman, 3M president, stationery and office supplies division (SOSD).

No tape, no scissors, no plastic

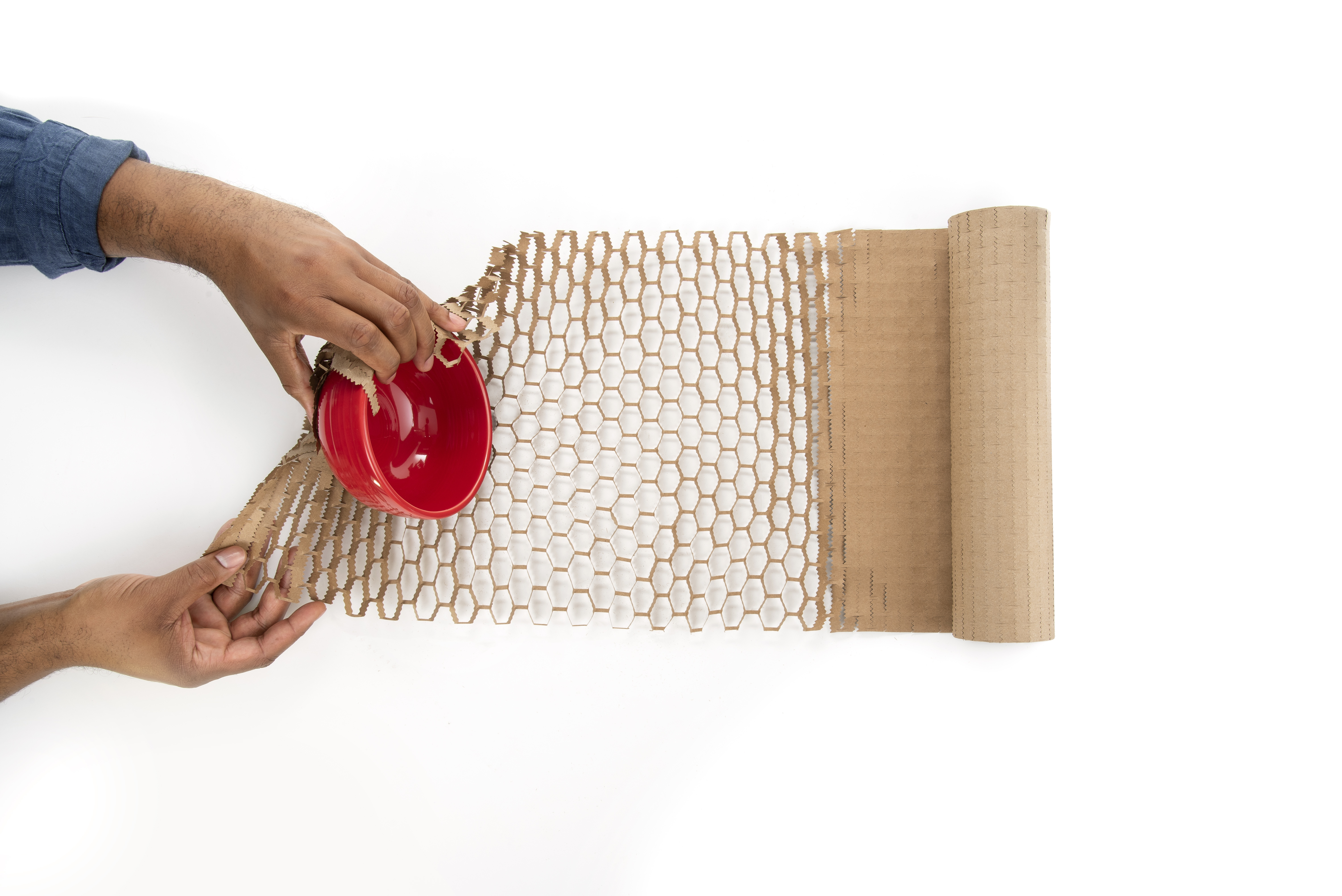

Cushion Lock tears by hand and its advanced self-locking technology readily fastens to itself, no scissors or tape needed to cut and secure. Simply pull Cushion Lock from the roll to expand it, wrap it around the item in a 360-degree fashion, tear the paper off the roll by hand, and place the wrapped item into box for nested protection for shipping, moving or storing. The Scotch Brand product development team rigorously tested Cushion Lock to ensure it successfully protects fragile items during the handling and transportation process.

A 1,000-foot Cushion Lock roll ideal for high volume shipping needs was introduced last fall at select office supply retailers and a convenient 30-foot-long roll for those with occasional shipping needs is now available at Target, Staples, and Amazon, with more retailers to come this year.

Cushion Lock stores flat on the roll, using up to 80% less storage space compared to traditional plastic cushion wrap. In addition, each 1,000-foot roll of Cushion Lock offsets up to nine pounds of plastic compared to traditional cushion wrap solutions, making the product well-positioned to help 3M reach its goal of reducing dependence on virgin fossil-based plastic by 125 million pounds by 2025.

Cut! And that’s a wrap

Kiragami, the Japanese art of paper-cutting and folding, is key to this inventive new product that turns a flat sheet of paper into a three-dimensional product through a design and process involving a little tension and a lot of precise cuts.

Since 2013, Tom Corrigan, a 3M SOSD product development specialist, had been experimenting with kirigami patterns that allowed materials to expand and drape over objects, yet remain flat. But in mid-2019, he talked with some coworkers about creating a packaging material that could expand and become thicker. He went back to the cutting board and came up with a design that allowed sections of the paper to turn a full 90 degrees, essentially thickening the material many times its original depth.

“It becomes three-dimensional and creates full structures that are now vertical, so they can take huge forces,” Corrigan explained. “Once it's rotated 90 degrees and you put your hand on it, you could feel how much stronger it was.”

A team formed around the new product in November 2019, but within a few months had to work remotely because of the pandemic. And then the shipping boom began.

“The product really became prioritized from a consumer lens. Shipping was increasing because people weren't traveling anymore, so they were instead sending things in the mail,” said Jennie Haight, the SOSD new product marketing manager on the project. “And along with the increase in ecommerce and consumer shipping, the whole topic around waste in packaging was growing.”

The team continued its research and development in earnest, using lab time when available but mostly confabbing over product iterations via webcam and makeshift at-home test labs. Once they landed on the kirigami design, the manufacturing had to be moved out of the lab to large-scale production, which presented its own series of challenges. But overcoming those manufacturing challenges resulted in yet another 3M trade secret.